Zaiput membrane-based separators enable, with appropriate configuration, continuous separation of chemical species leveraging the principle of Partition Chromatography.

When Crystallization isn’t an option, CLL-PC provides a cost-effective solution to separate chemical species at a fraction of the cost of Simulated moving bed Chromatography.

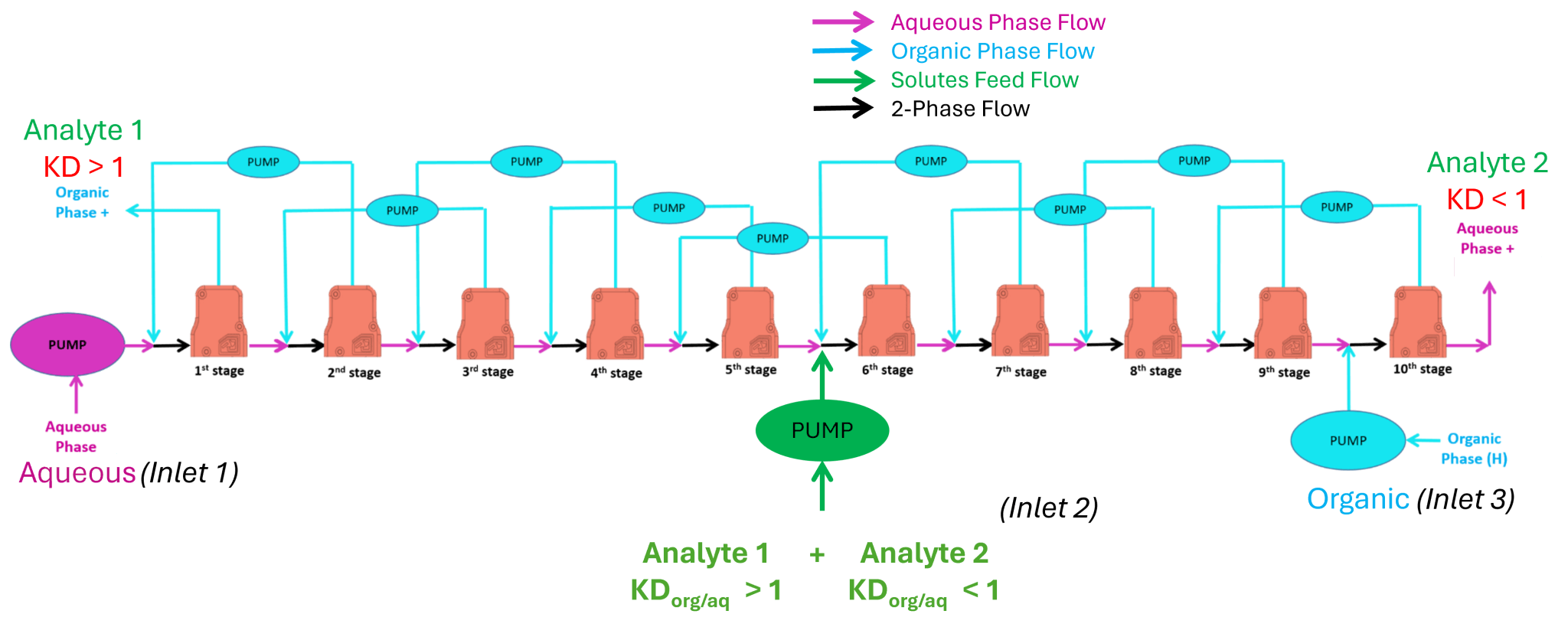

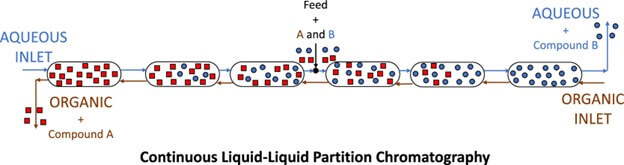

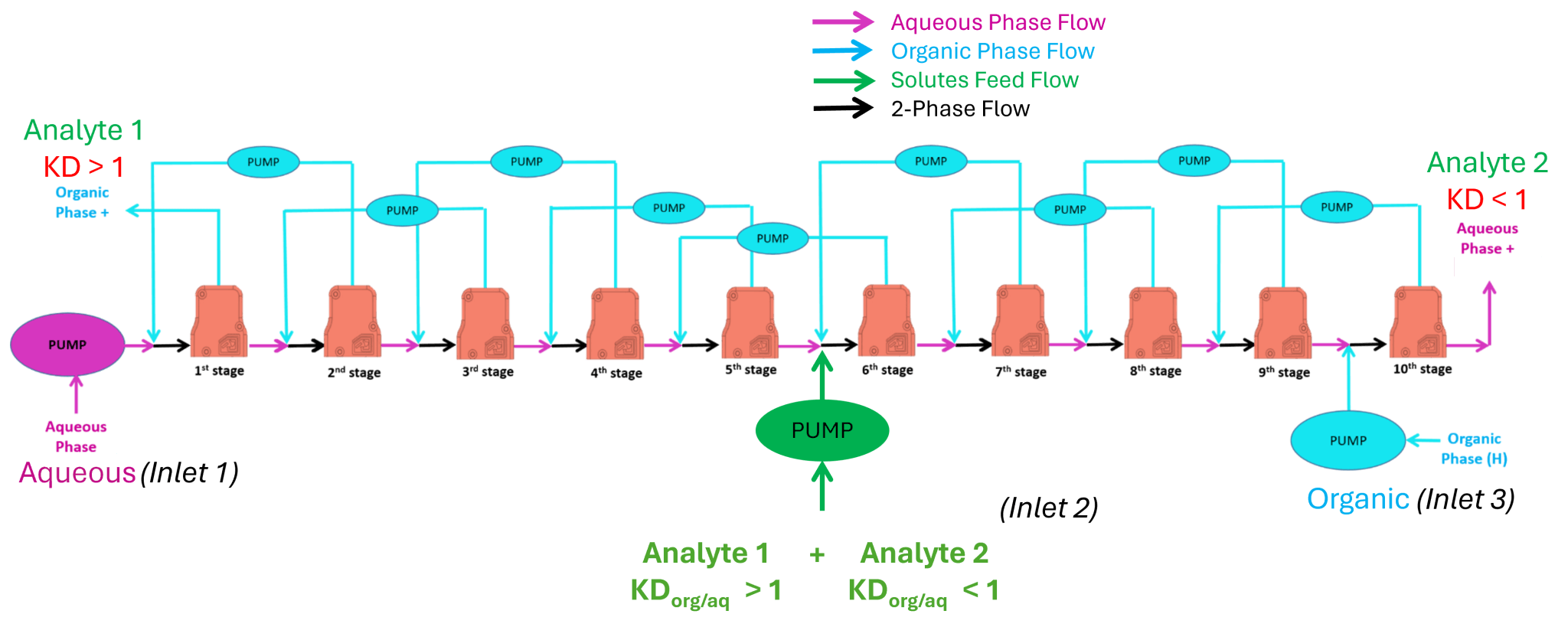

Our method and related hardware offer the ability to carry out partition chromatography in a continuous manner. In our approach phase separation is accomplished with the Zaiput membrane-based liquid-liquid separators.

An adequately designed multistage extraction process with >5 stages allows to retrieve a phase with one species ( or one group of species) and another phase with the other species (or another group of species). In other words, very much like simulated moving bed chromatography the technique allows to separate a continuous feed into two streams each one with a distinct group of species in it.

The concepts of Partition Chromatography have been developed in the 40s, a Nobel prize in Chemistry was awarded to Martin and Since in 1952 for this discovery.

Very much like solid stationary phase chromatography where the travel speed of analytes is altered by interaction with a solid stationary phase thus achieving separation, in partition chromatography ( also known as liquid-liquid chromatography) the travel on analytes is altered by interaction (partitioning) with a second phase that, in this case, is also a liquid.

The challenge of this approach has always been its practical implementation Several approaches have been presented over the decades. All of them have a high complexity of the mechanical apparatus involved. More recently the use of centrifugal force ( Centrifugal partition chromatography, CPC) has gained some popularity despite the challenges of associated high pressure in rotating systems.

An adequately designed countercurrent multistage extraction process with >5 stages allows to retrieve a phase with one species ( or one group of species) and another phase with the other species ( or another group of species). In other words, very much like simulated moving bed chromatography the technique allows to separate a continuous feed into two streams each one with a distinct group of species in it.

The process design requirement for a countercurrent liquid-liquid extraction (LLE) process to provide a continuous partition chromatography type of separation is to ensure that the species to separate have one partition coefficient greater than 1 and the other lower than 1. The greater is the difference between the partition coefficients the lower is the number of stages needed.

CLL-PC allows separation of chemical specie leveraging differences in partitioning of the species not two different liquid phases. Applications are across a wide spectrum, in the literature partition chromatography has been applied in several areas such as separation of chiral molecules, natural products , isomers in general.

The Zaiput unique approach to continuous Partition Chromatography has two key features :

To develop an application there are 5 key steps to follow iteratively until adequate performance is achieved:

Viano, R., Adamo, A., et al., 2023. Organic Process Research & Development, 27(12), pp.2296-2308.