Inline purification in continuous flow synthesis – opportunities and challenges

Overview of flow technologies

This paper from University College Dublin does a great job of highlighting flow technologies that have addressed or have yet to address common workup steps in chemical synthesis. Zaiput’s continuous phase separators were the primary focus of the Inline extractions/separations section where they were identified as the key technology in this space. The article also highlighted what they perceived to be a major shortcoming in Zaiput’s phase separation technology – the scalability of flow rates and challenges with solid accumulation.

Since this writing, Zaiput has addressed these concerns by releasing a large scale 40 L/min separator and focused on prefiltration techniques to minimize fouling concerns. Today the scalability is direct and easily done from the lab to production.

Click on this link to read the full paper

Zaiput technology for continuous phase separation

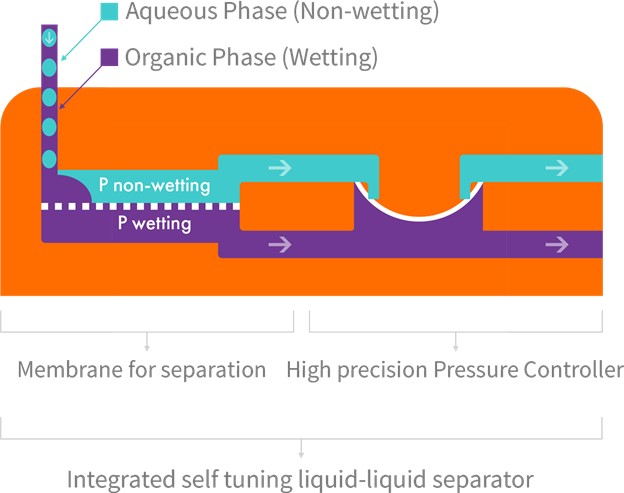

Zaiput Flow Technologies’ patented separators provide continuous separation of an immiscible phase (liquid-liquid or gas-liquid) by leveraging differences in wetting properties of the liquids onto a porous membrane.

-

- When a stream composed of two phases (for example: an aqueous liquid and an organic liquid or a gas and a liquid) enters the separator, one phase will have an affinity for the membrane and fill the pores (this is referred to as the “wetting” phase), and the other phase will be repelled and will not fill the pores (this is referred to as the “non-wetting” phase).

- Once the membrane pores are filled with the wetting phase, a pressure differential is applied between the two sides of the membrane. This pressure differential is finely adjusted by Zaiput’s patented internal pressure controller to apply just enough pressure to “push” the wetting phase without forcing the non-wetting phase through the pores (see figure below). The separator is designed to maintain a constant pressure differential across the designated flow rates even when conditions are fluctuating. As a result, the separator can be used as a “plug-and-play”, modular unit.

- A key aspect of the technology is that it exploits differences in wettability and surface forces to accomplish the separation; as a result, the device can separate liquids with the same density and emulsions with continuous operation.

Zaiput also offers back pressure regulators, specifically designed for the needs of the flow chemist. Our BPRs feature a unique combination of high accuracy and precision, broad pressure range and outstanding chemical compatibility in a compact format.