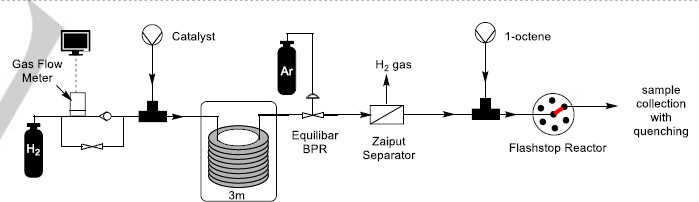

Fast Isomerization before Isomerization-Hydroformylation Probing the Neglected Period with a Novel Microfluidic Device

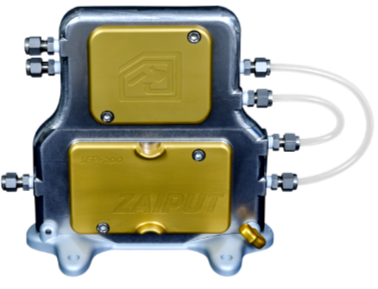

Zaiput use as a gas-liquid separator

A very common use case for Zaiputs’ separators is in gas/liquid separations following hydrogenation reactions. These reactions are commonly run in the presence of excess hydrogen to push the reaction toward completion, but this excess hydrogen needs to be separated from the liquid stream post-reaction. Zaiput separators’ small internal volume and high performance make this gas liquid separation safer and easier than traditional batch methods.

Researchers at Lianyungang Institute in China used a SEP-10 for this exact application. For more on their work, you can read their paper here.

Zaiput phase separation technology

Zaiput phase separation technology is routinely used in flow chemistry applications and in flow chemistry laboratories around the world. Our membrane-based separators allow for continuous phase separation exploiting differences in the wetting properties of two immiscible or partially miscible liquids onto a porous membrane. This results in continuous, accurate, and density-independent phase separation. While the technology is primarily used for liquid-liquid separations, also gas liquid separations can be performed with our technology, for example, to safely remove excess hydrogen after a hydrogenation.

Main features of phase separation by Zaiput:

- Bench-top to plant scale

Our devices are well-characterized and linearly scalable from lab to pilot to production. - Independent of density

The operating principle behind the technology is based on a liquid’s wettable nature, so it works with any liquid-liquid system regardless of their density difference. - Excellent chemical compatibility

Machined in materials with excellent chemical resistance, Zaiput separators work with a wide range of organic solvents, in acidic and basic solutions. - Easy usage and maintenance

Plug-and-play functionality at all scales. - Continuous operation for batch/flow chemistry

Our devices can be easily used and integrated within either a batch process or a continuous one. - Cost-effective

The cost of our devices is less than that of rival technology. Because of their efficient operation and low maintenance requirements, our devices will lower your operating expenses - Separate emulsions with ease

Instead of using agitation to form microdroplets, we improve mixing by using a flow pattern that has a large surface area, thus avoiding emulsions that generally cause separation issues. Existing emulsions tend to break as they encounter the membrane. - Minimal internal volume

Our devices eliminate the need for moving or coalescing parts, and also have a drastically reduced dead volume. - Green technology

Our devices have excellent separation performance and high extraction efficiency, reducing solvent consumption. They are suitable for any chemical process, from bulk to high-value chemical industries. - Pressure rating

Zaiput separators can be employed in line with a pressurised process because to their metal shell construction. (up to 290 psi/ 2 MPa). - Inherently safe

No electricity is required, minimal internal volume and no headspace

Finally, the separators can used in a sequence, for multi-stage extractions