Extractive Technology Innovations for the Metal Recycling Industry

Solvent extraction for the hydrometallurgy industry

Recycling metals, especially Rare Earth Elements, and other precious metals is a critical industry for both environmental and economic sustainability for countries around the world. How will the industry innovate as the demand for these valuable metals continues to outstrip supply? This blog post dives into how Zaiput can solve challenges facing the industry.

The metals recycling industry has become increasingly important in recent years due to the growing demand for precious/rare earth metals and the increasing awareness of the need to reduce waste and conserve natural resources. Metals, such as lithium, cobalt, neodymium, praseodymium, germanium, and others are highly valuable and have a wide range of uses, including in electronics, renewable energy applications, and medical equipment. However, the production of these metals can be highly resource-intensive and environmentally damaging. Recycling precious metals can help to reduce the environmental impact of their production and provide a sustainable source of these valuable resources.

Despite the importance of precious metal recycling, the industry is facing a number of challenges. One of the biggest challenges is the lack of efficient and effective technologies for separating and refining precious metals from complex materials. Many electronic products, for example, contain small amounts of precious metals that are difficult to extract using traditional methods. The use of new technologies can help to overcome these challenges and make the recycling process more efficient and cost-effective.

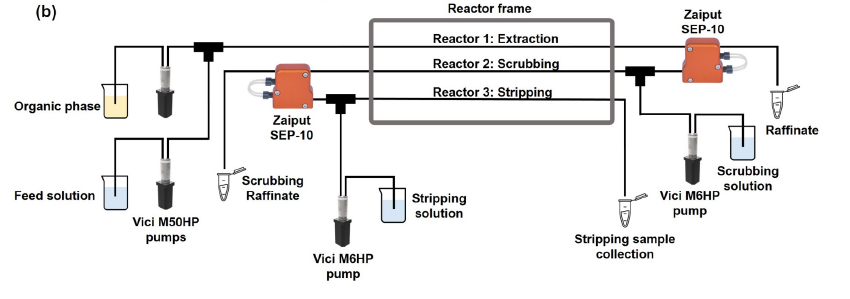

One area of innovation is the use of membrane technologies to improve liquid-liquid solvent extraction. Technologies like those from Zaiput Flow Technologies have been shown to intensify extractions, with the specific advantage of reducing the size and internal volume of units relative to the throughput of the technology. These units combine high-efficiency in-line mass transfer with instantaneous membrane phase separation to provide extractions at theoretical efficiency. Previous works have shown their effectiveness in the metals extraction industry like this paper from KU Leuven in which researchers integrated extraction, scrubbing, and stripping to purify germanium from zinc refinery residue leachate.

The large throughput-to-volume ratio of this technology lends itself to modularized, distributed production of recycled metals. In a world where supply chains have been shown to be easily disrupted and each country wants to nationalize its own supply of valuable metals, a decentralized model of production is likely to arise. In this context, recycling plants will have to be stood up with smaller vessels and capital requiring new technologies to take the place of traditional mixer settlers and centrifuges. Here too, Zaiput’s separators bring significant advantage, with throughputs up to 40 L/min with internal volumes of 5 L or less, in a footprint not much larger than a refrigerator.

However, there are also challenges associated with the adoption of new technologies in the recycling industry. One of the biggest challenges is the cost of research and development. Developing new technologies can be expensive and time-consuming, and the risks associated with failure can be high. Further, the value of the materials involved can be prohibitively high for in-depth process analysis. To circumvent this, companies will often look to simulation to design new processes, but real results often vary from simulation outcomes. Here again, Zaiput’s technology can help companies improve outcomes by providing the smallest available countercurrent solvent extraction technology. With an internal volume of just 3 mL/ theoretical stage, Zaiput’s countercurrent extraction platform MS10 gives researchers the ability to redesign their extractions and put their simulations to the test, all while keeping material waste at a minimum. This ability to flexibly experiment with extraction conditions could hold the key to dramatically improving extractive yields during metal processing – allowing companies to reduce solvent use and produce more product.

The need for new technologies in the precious metal recycling industry is clear. The environmental and economic benefits of recycling precious metals are significant, and the adoption of new technologies can help drive a movement toward a more circular metals economy. Companies like Zaiput and others will continue to provide tools to the industry so that they can innovate on our current way of extracting metals.