In-line membrane-based phase separation and Ionic Liquids

Ionic Liquids and in-line separation

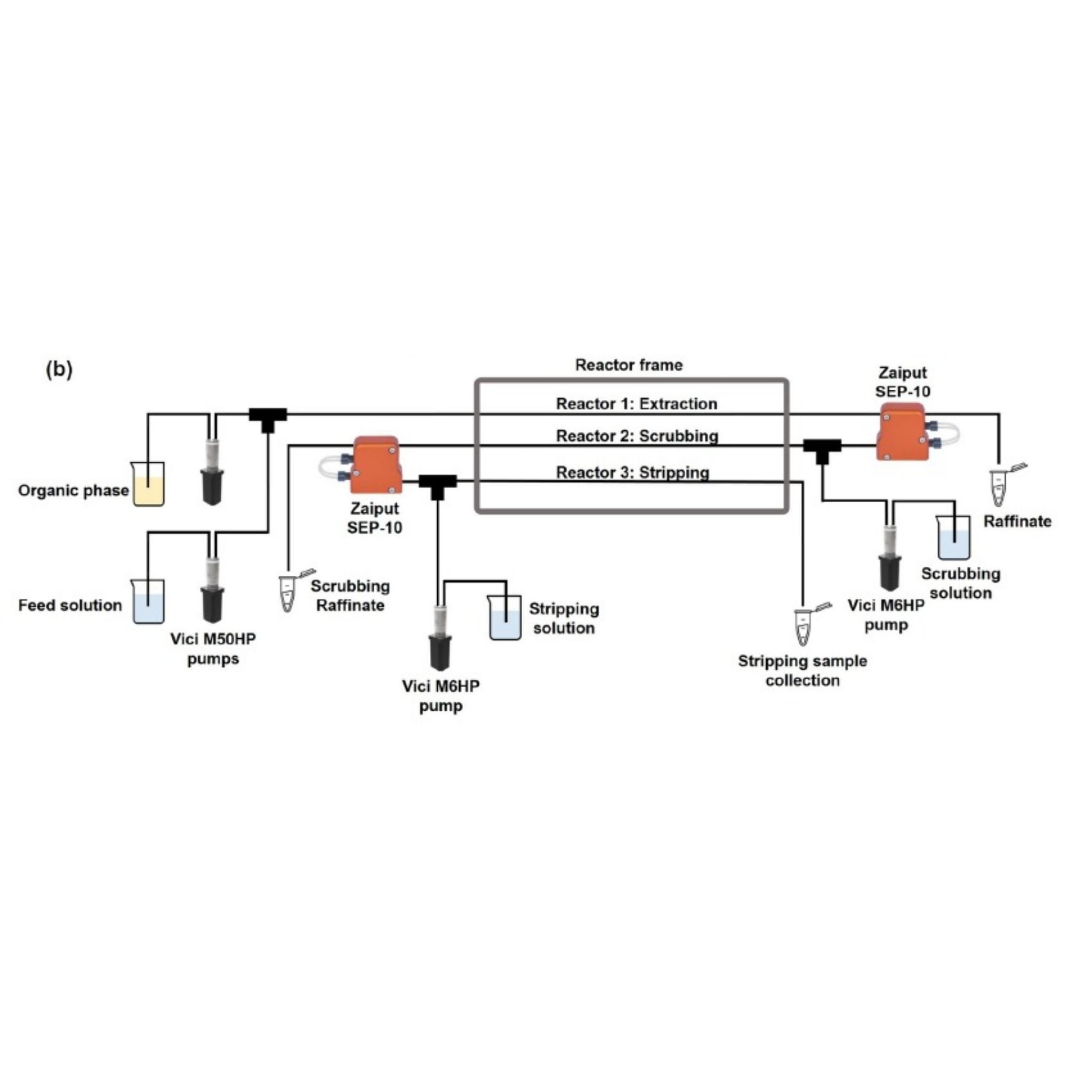

This paper from researchers at KU Leuven demonstrates various capabilities of ionic liquids and their applicability with Zaiput Flow Technologies in line separators.

Advantages of hydrometallurgy applications with Zaiput

Despite the importance of precious metal recycling, the industry is facing a number of challenges. One of the biggest challenges is the lack of efficient and effective technologies for separating and refining precious metals from complex materials. Many electronic products, for example, contain small amounts of precious metals that are difficult to extract using traditional methods. The use of new technologies can help to overcome these challenges and make the recycling process more efficient and cost-effective.

One area of innovation is the use of membrane technologies to improve liquid-liquid solvent extraction. Technologies like those from Zaiput Flow Technologies have been shown to intensify extractions, with the specific advantage of reducing the size and internal volume of units relative to the throughput of the technology. These units combine high-efficiency in-line mass transfer with instantaneous membrane phase separation to provide extractions at theoretical efficiency.

With an internal volume of just 3 mL/ theoretical stage, Zaiput’s countercurrent extraction platform MS10 gives researchers the ability to redesign their extractions and put their simulations to the test, all while keeping material waste at a minimum. This ability to flexibly experiment with extraction conditions could hold the key to dramatically improving extractive yields during metal processing – allowing companies to reduce solvent use and produce more product.