Zaiput Flow Technologies’ back pressure regulators are specifically designed for the needs of the flow chemist. Our devices feature a unique combination of high accuracy and precision, broad pressure range and outstanding chemical compatibility in a compact format.

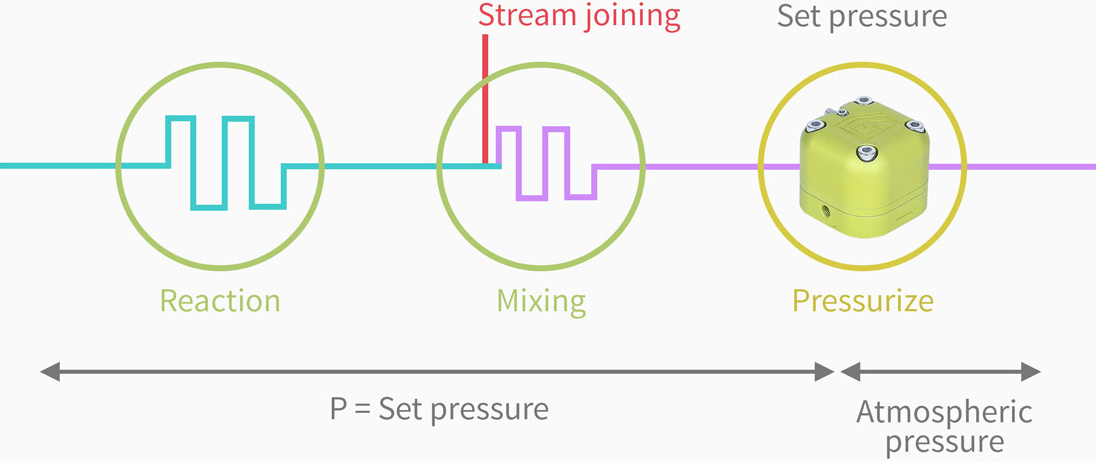

The back pressure regulator compares the pressure of the fluid to be controlled (main stream) to a reference pressure. Flow of the main stream is allowed only if its pressure meets the reference pressure.

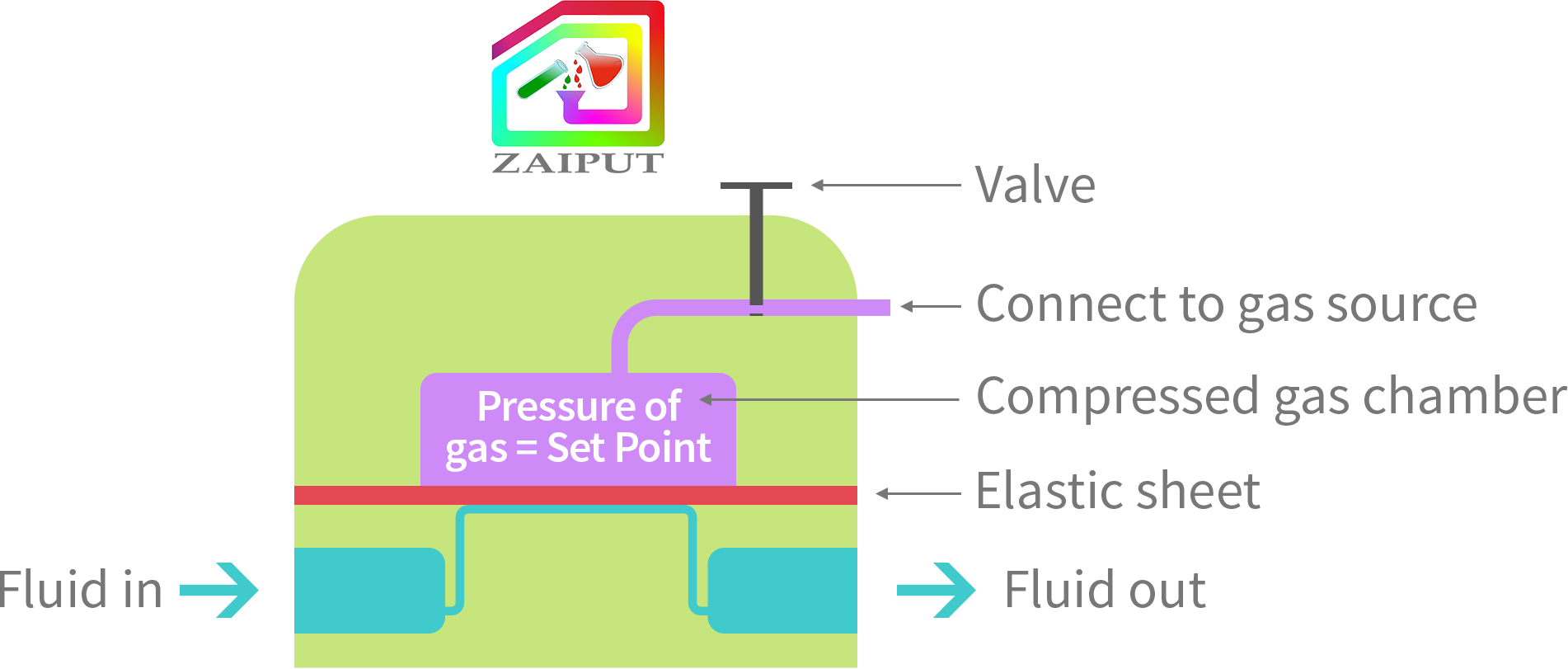

In addition, our pressure regulators have the unique feature that the set point is selected by the user. The user selects the back pressure set point by pressurizing air inside a dedicated chamber of the device. The set point is equal to the pressure of the air inside the device.

Zaiput’s BPRs have a chamber that the user fills with compressed air. The pressure of the inputted air represents the back pressure set point of the device. An elastic sheet intercepts the process fluid flow path and allows a comparison of the pressure of the process fluid to the reference pressure. In other words, the process fluid can flow through the device only when its pressure is equal to the reference pressure.

Zaiput’s BPRs are carefully designed with chemically compatible materials as well as a reliable dynamic response of an elastic sheet. With a sealed valve, the BPRs can be used in two modes:

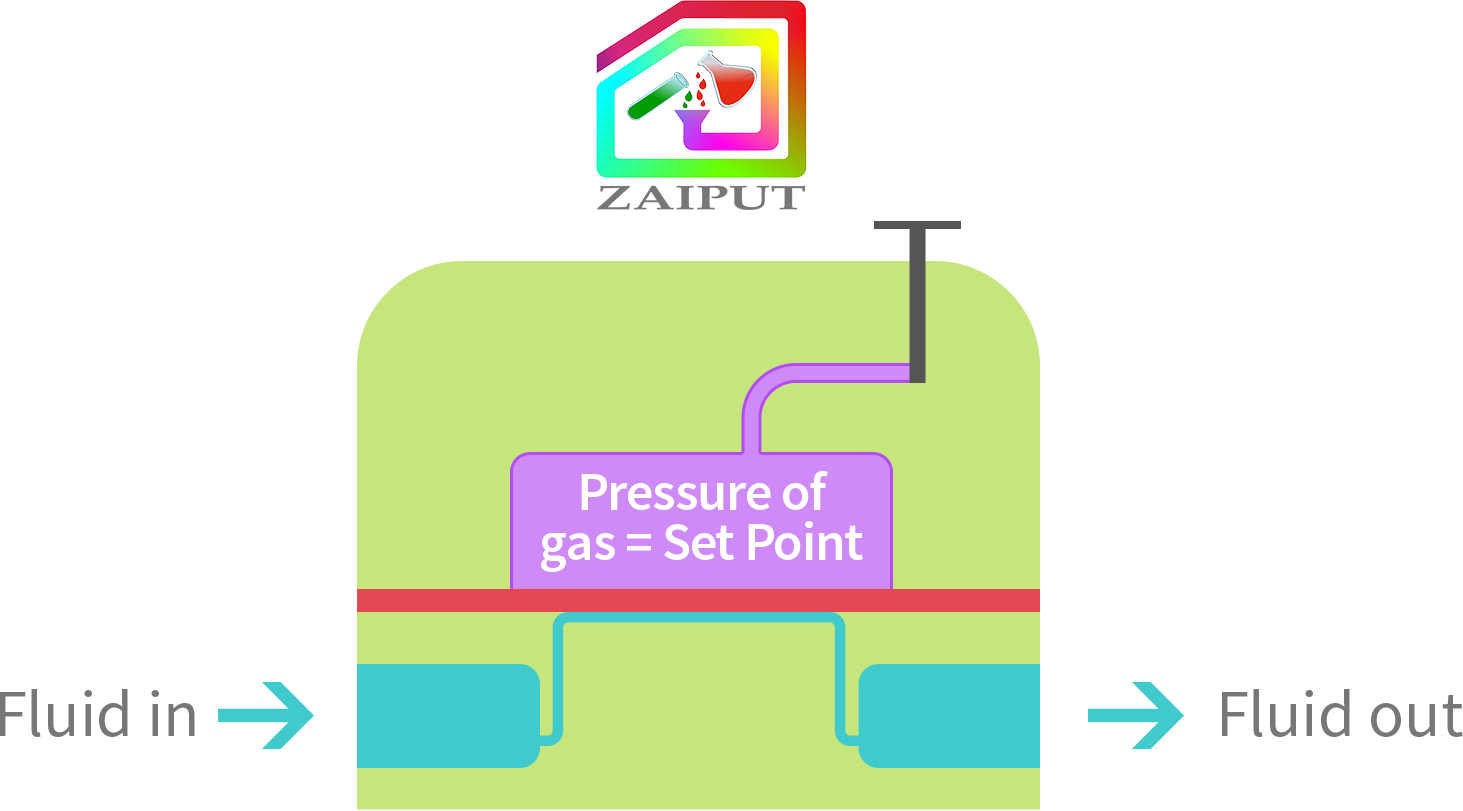

In this mode, the user compresses gas into the chamber of the device at any certain pressure P. Then, the user manually closes the valve; P inside the chamber is now at the set point. The user can disconnect the BPR from the pressure source (e.g., gas tank). If another set point is required, this procedure can be repeated by setting the pressure of the top chamber to the new value. The advantage is that a gas tank is not required for operation.

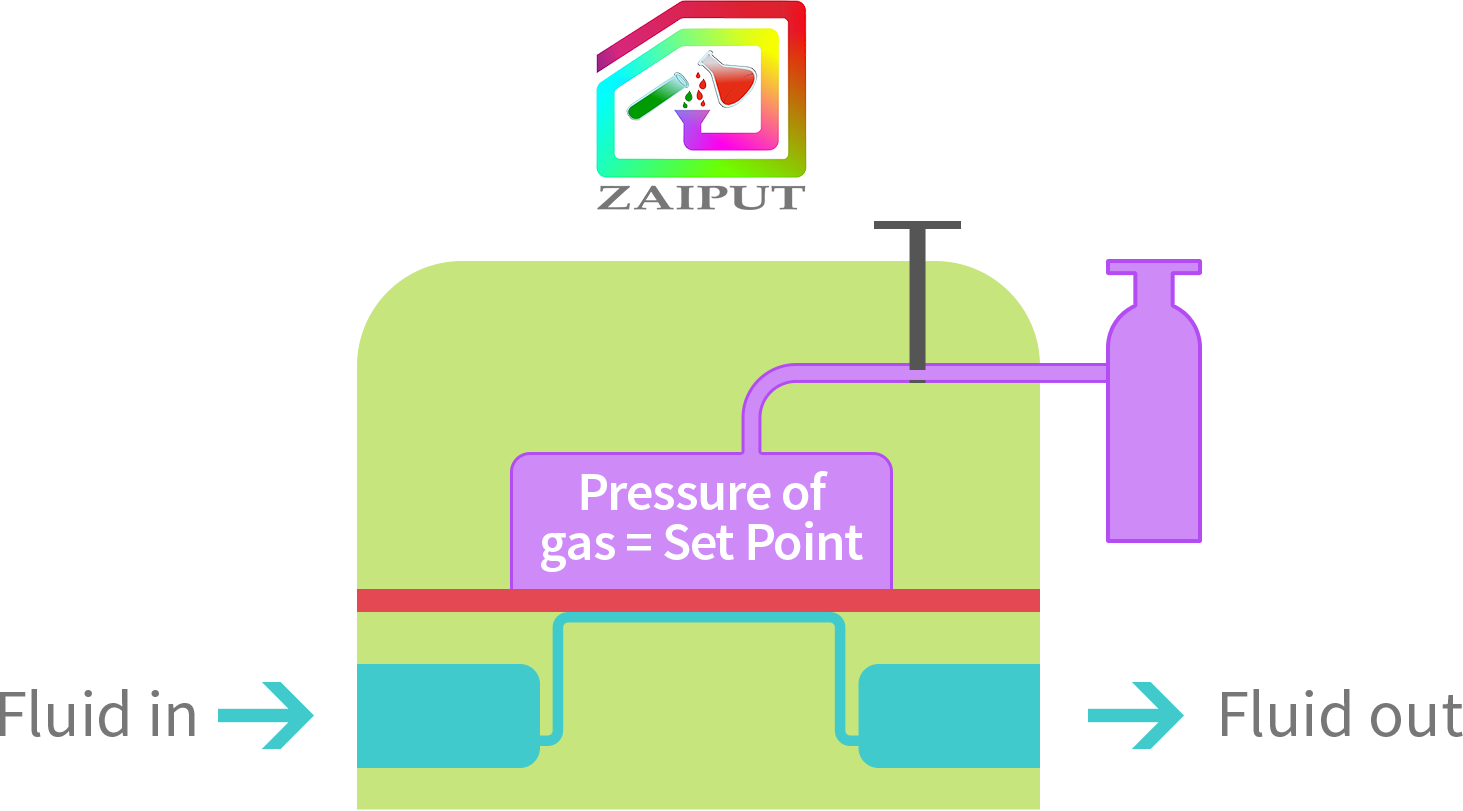

Some processes require the fluid pressure to dynamically change over the course of operation. The Zaiput BPR is able to provide such a continuous pressure setting. To achieve this setting, the user connects the Zaiput BPR to the gas/pressure source. Note that the valve is left open. By changing the pressure of the gas source (e.g., the regulator of the gas tank), the set point or P is dynamically changed.

Note that the Zaiput BPR sets a minimum level of pressure for the main fluid flow. If multiple BPRs are placed in series, the pressure of the fluid flow will be equal to the highest pressure set point (i.e., not the sum of the multiple set points). As a result, the device can also be used as a relief valve. Each BPR comes with a connection tube (the external pressurized gas source is not included).

|

||

|

||

| Part Number | BPR-10 | |

|---|---|---|

| Total Flow Rate | 0.05-20 ml/min (for high accuracy) | |

| Max Set Point Pressure | 2 MPa (290 psi) | |

| Dimensions | 52 x 52 x 44 mm | |

| Max Inlet Pressure | 5 MPa | |

| Max Operating Temp | 90 ℃ | |

| Process Fluid Ports | 1/4″ UNF – 28 flat bottom | |

| Wetted parts | Perfluorinated polymers (ETFA, PFA) | |

| Error | < 1% | |

|

||

|

||

| Part Number | BPR-1000 | |

| Total Flow Rate | 20-1000 ml/min (for high accuracy) | |

| Max Set Point Pressure | 2 MPa (290 psi) | |

| Dimensions | 97 x 97 x 64 mm | |

| Max Inlet Pressure | 5 MPa | |

| Max Operating Temp | 90 ℃ | |

| Process Fluid Ports | 1/4″ OD tubing with Swagelok PFA fittings and our compression nut | |

| Wetted parts | Perfluorinated polymers (ETFA, PFA) | |

| Error | < 1% | |

*Scroll left to see more of the table

Zaiput BPRs work well with multiphasic fluids such as liquid/liquid and gas/liquid. They are also capable of handling small amounts of solid particles with diameters smaller than 150-200 μl.

The set point of the Zaiput BPRs are adjustable by compressed air/gas. The Zaiput BPR have been designed to maintain a stable pressure with negligible variation (± 5%).

The inlet and outlet of the Zaiput BPR-10 and BPR-1000 are listed in the specifications tab.

Zaiput BPRs are designed to be leak-proof. They have been characterized to be able to maintain a stable pressure for at least 10 days.

A back pressure regulator is used to regulate inlet pressure, so an upstream fluid will be pressurized to the set point. On the other hand, a pressure regulator regulates outlet pressure, so a downstream fluid will be pressurized to the set point.

Unlike many other products on the market, Zaiput BPRs do not come with a factory-preset pressure. Instead, users are allowed to precisely set the Zaiput BPR to any pressure within a recommended operating range (1 – 290 psi). Zaiput BPRs are also easy-to-use and chemically compatible.

All of the wetted parts inside the Zaiput BPR are made of highly chemical-compatible materials. The metal shell will not be in contact with the fluid. They can handle most organic solvents as well as acidic solutions. Contact our technical support team for questions about chemical compatibility.

The recommended operating flow rate is between 0 and 1000 mL/min, depending on the unit.

The internal parts of Zaiput BPRs are made of polymers. Therefore, the recommended operating temperature is below 130 ˚C. For any application at higher temperatures, consult our service team for a customized solution.